Adventures in building your own DIY-CNC

I guess you could say having never built anything like this I had to take my time and think about how I would approach it. Mostly based on the idea I would need to look at what controller option I would use. Many use LinuxCNC or base it off of some custom version of LinuxCNC. I decided not to go that route for tighter control of how the milling software works.

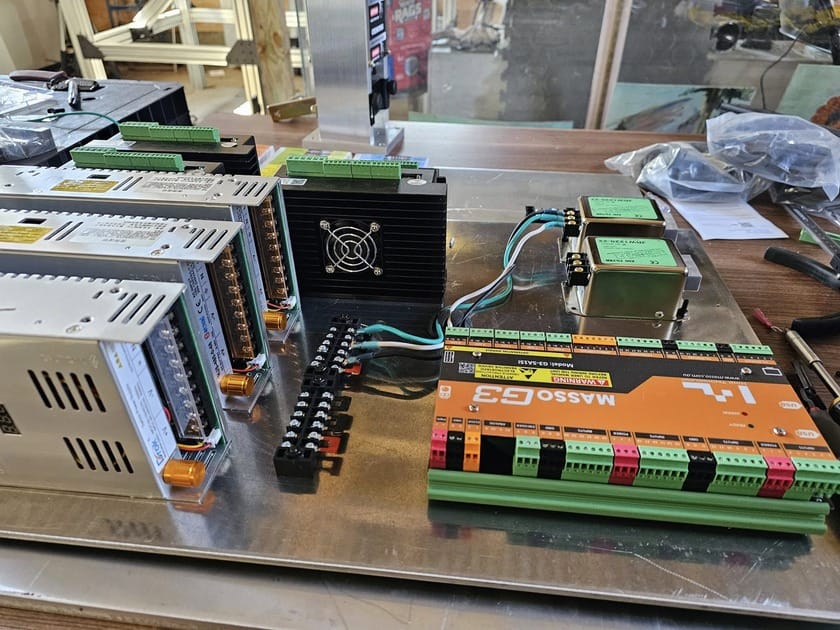

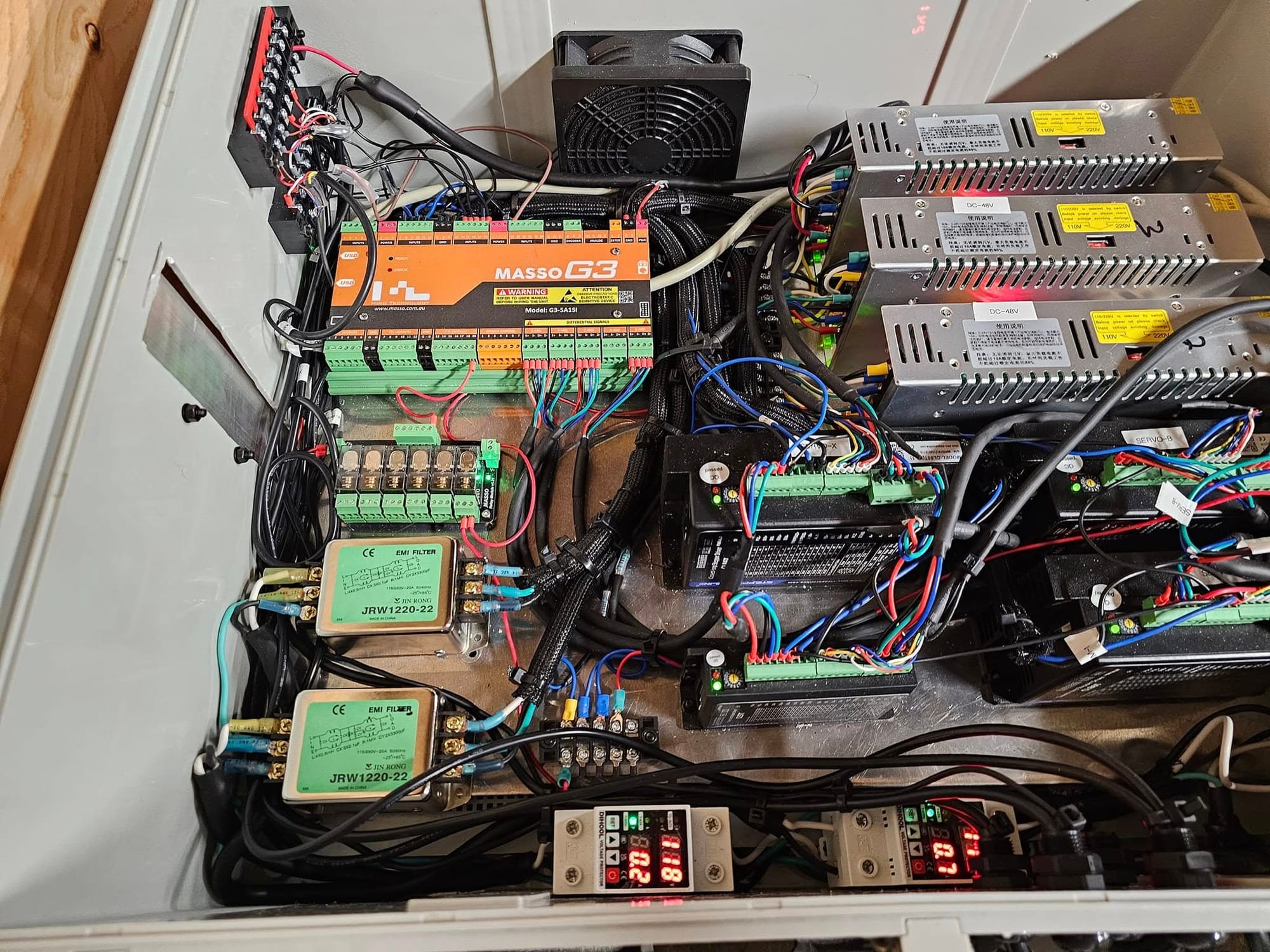

I ended up choosing MASSO G3 controller because it had everything on a central control screen including emergency stop on off buttons and a touch screen. The platform supports CNC and plasma cutting. Supports up to 5 axis and multiple USB inputs. To simplify the wiring I paid for the somewhat expensive option to having the controller external as well as the relays external. Below is the photo of the MassoG3 and the relay in the power and driver box.

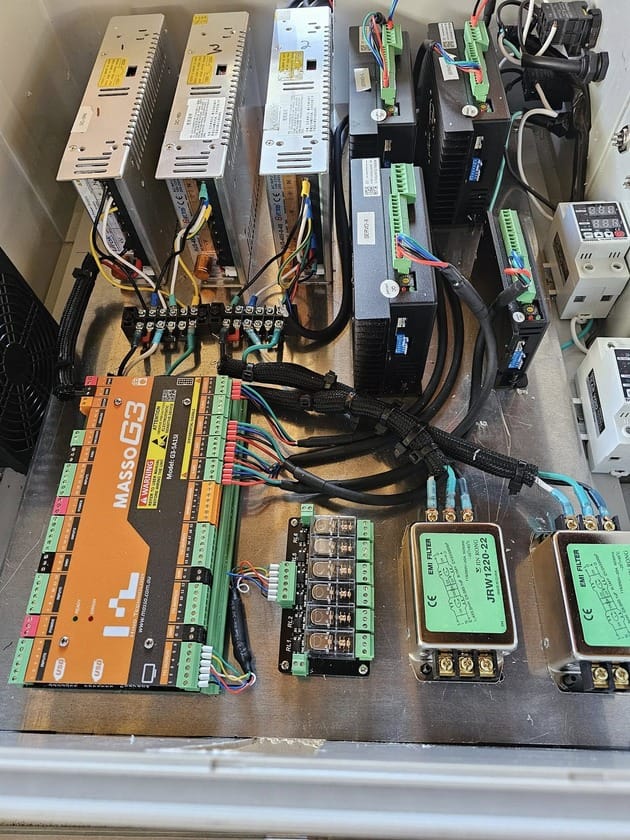

In there you see the two AC filters in green on the bottom right, two power relays and the four linear servo motor drivers as well as 5 volt DC, 12 volt DC and 24 volt DCs power supplies. The digital fuse relay are on the top far right. I drilled out an aluminum plate to mount everything. I added a 12 Volt DC fan on the left to cool everything in an enclosed box. I due to electromagnetic interference put the spindle driver in a separate box. This is not a photo of the completed build still had plenty of wires left to wire.

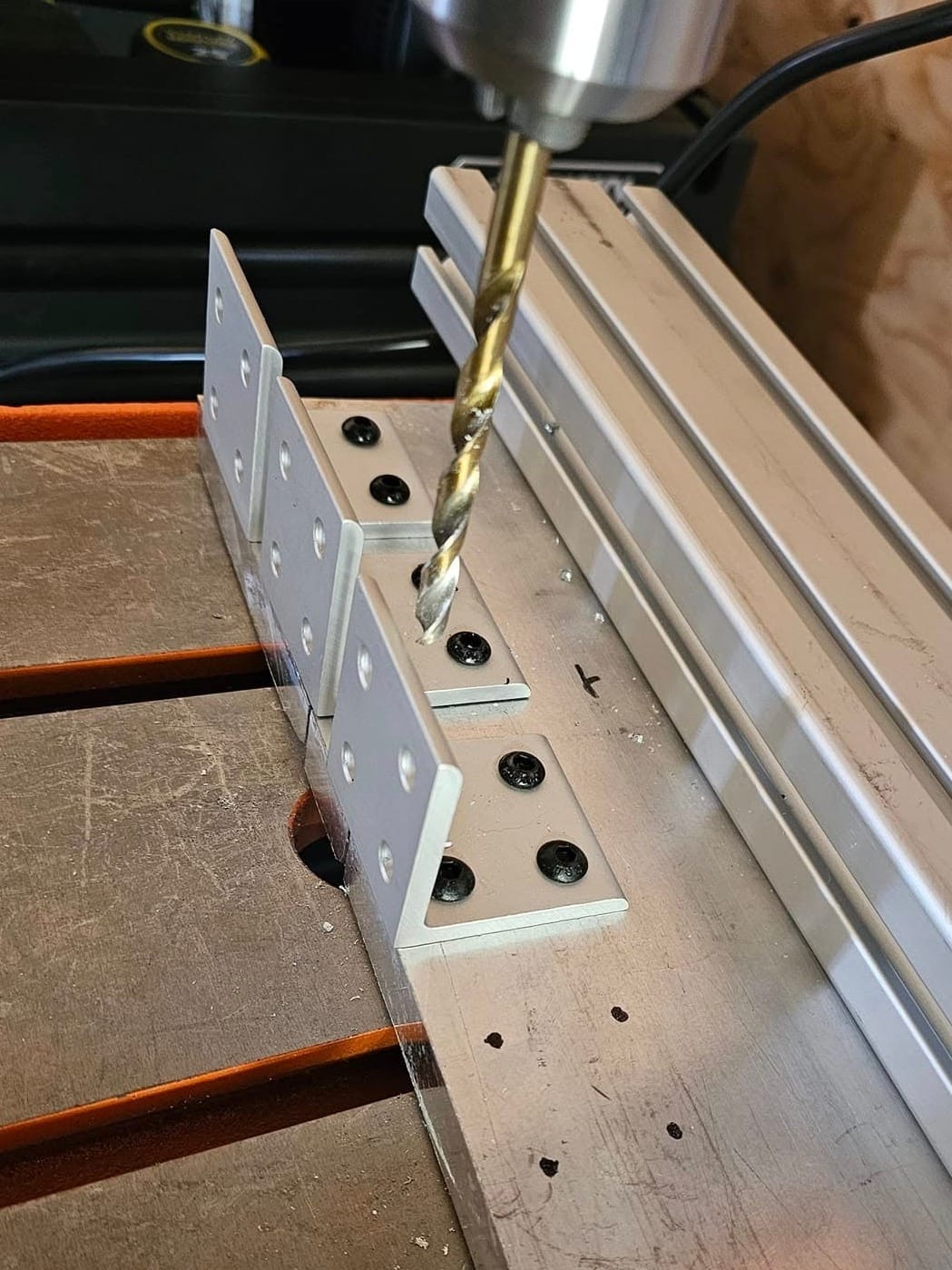

Here I am after I cut the 3/4 inch plate to size aligning and drilling the mounting holes for where my gantry will be mounted. That was done on my drill press and it took sometime because I could not afford to get it wrong.

I spray painted the the 3/4 inch aluminum supports that held the gantry, router, Z axis linear servo. That was a bit of a challenge but came out OK. They weigh like 30 lbs. each not including the gantry that is why I added a small lift when I work on the gantry. The total weigh of the gantry the supports and the spindle is higher then 120 lbs it seems.

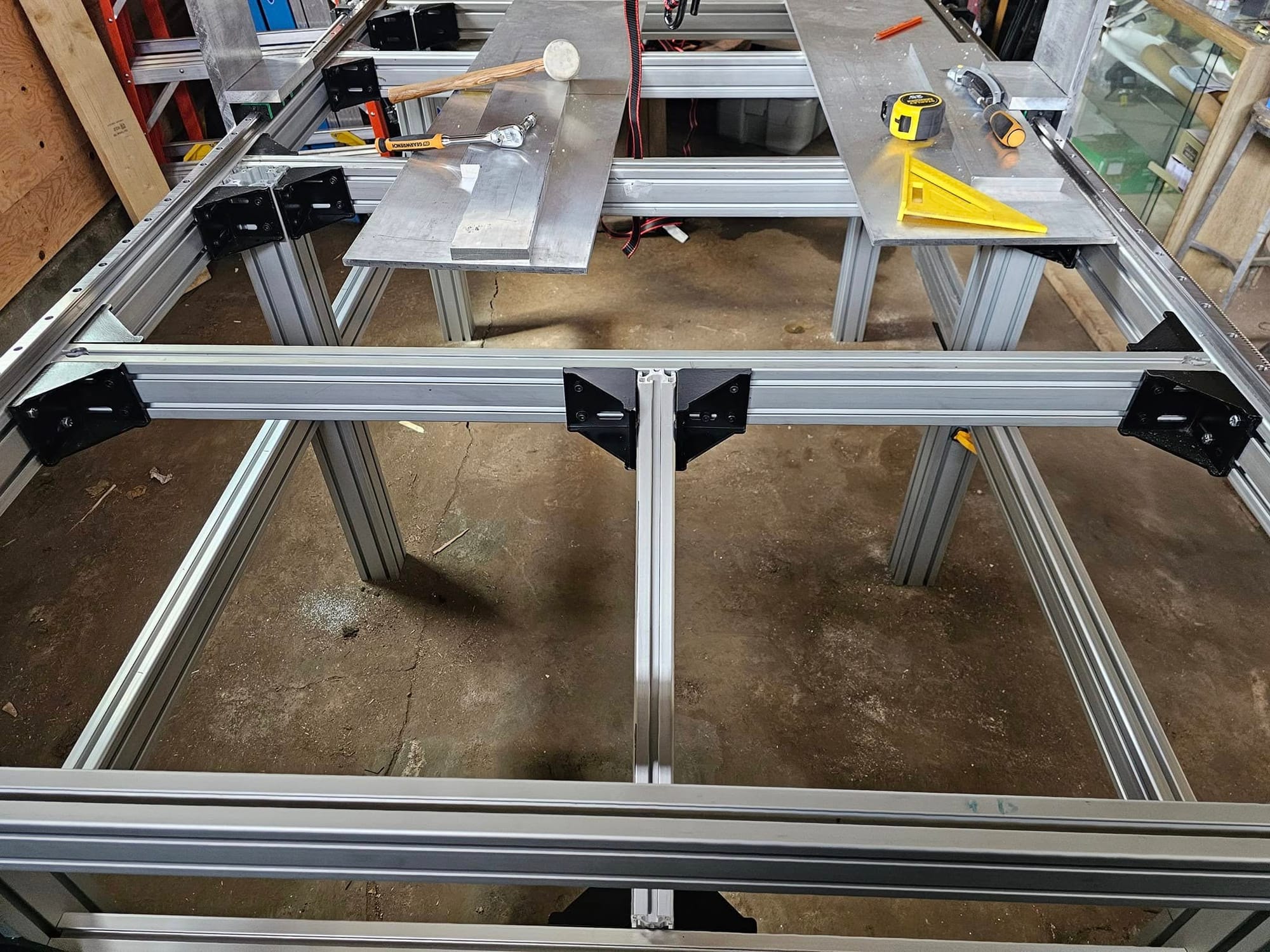

Then came building the based up various photos of each stage of the 4 X 7.8 foot table build. A lot of 1/4 inch aluminum plates to cut that will sit under the gantry. But below is many photos of the table build including aligning and leveling of the table legs.

This took a few days of cutting and getting the fit right as well as drilling out the holes to hold the plates down to the table. Below is the almost finished wiring for the controller, power supply box. It started to get a little wild lol running my two digital fuse relays in the photo below.

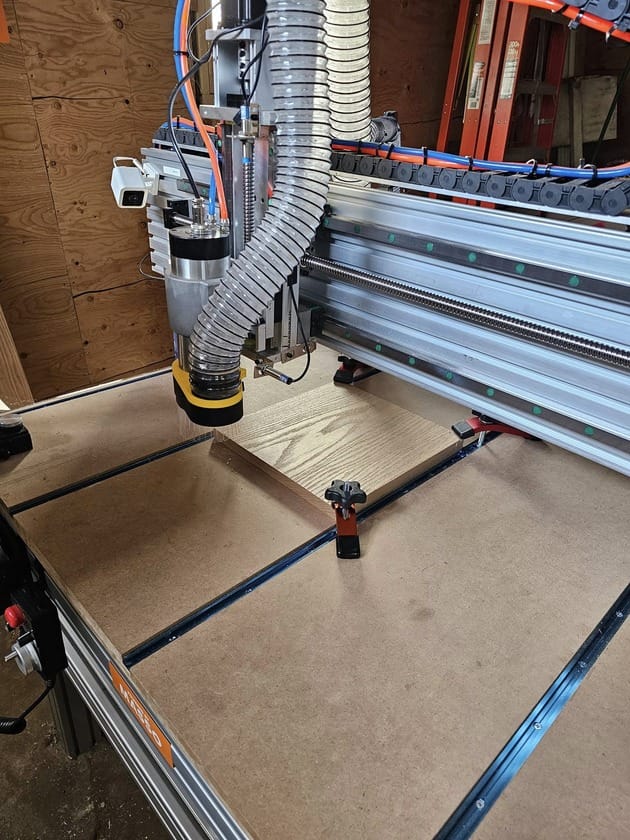

The DIY CNC is almost done as I am getting ready for my first cuts on the CNC.

This was a fun project from start to finish and levelling it all along the way was very time consuming. But the results allow me to change it relatively quickly if needed and the waste board I added another board on top because I have over 7 inches of travel.

Here is the photo of the spindle driver getting fitted for my metal encloser for the first time.

Well this is a quick overview of what was needed to build my DIY-CNC.